Introduction

Galvanized aluminum is becoming an increasingly popular choice in industries seeking corrosion-resistant metals that balance strength, weight, and longevity. In this article, we explore what galvanized aluminum means, its key properties, advantages and disadvantages, typical applications, and tips for proper use and maintenance. Whether you’re planning a new structure, product, or infrastructure project, understanding galvanized aluminum will help you make smarter material decisions.

What Is Galvanized Aluminum?

To understand galvanized aluminum, it helps first to recall how galvanization works. Traditional galvanization coats a base metal (often steel) with a layer of zinc to protect it from corrosion. In contrast, galvanized aluminum refers to aluminum surfaces that receive a protective metallic coating (often zinc or zinc-alloy blends) to improve corrosion resistance. The process can vary but often involves electroplating, conversion coatings, or incorporating zinc/aluminum alloys.

In effect, galvanized aluminum brings together the lightweight and non‑magnetic nature of aluminum with the sacrificial protection conferred by a galvanic coating. For clarity, some references mislabel zinc-coated aluminum as “galvanized,” while others use “aluminized zinc” or “zinc-aluminum coatings” in more technical terms.

Key Properties of Galvanized Aluminum

Corrosion Resistance

One of the primary reasons to choose galvanized aluminum is enhanced corrosion protection. The zinc or zinc-alloy coating serves as a sacrificial layer: when portions of the coating are damaged, the zinc corrodes preferentially, shielding the underlying aluminum. This is especially beneficial in humid, coastal, or industrial environments.

Strength and Durability

While pure aluminum is relatively soft compared to steel, galvanized aluminum can maintain good mechanical strength, depending on base alloy and coating thickness. The underlying aluminum must be selected carefully for strength, while the coating itself offers an extra barrier layer without dramatically weakening the substrate.

Weight and Density

Aluminum is valued for its low density (~2.7 g/cm³), which is much lighter than steel. When coated, galvanized aluminum retains most of that weight advantage, making it ideal in applications where weight savings matter, such as in transportation or structural components.

Electrical and Thermal Conductivity

Aluminum is an excellent conductor of electricity and heat. Applying a galvanic coating slightly changes surface conductivity but typically does not drastically impair the aluminum’s usefulness in thermal or electrical roles—though it may need evaluation depending on the coating thickness and alloy.

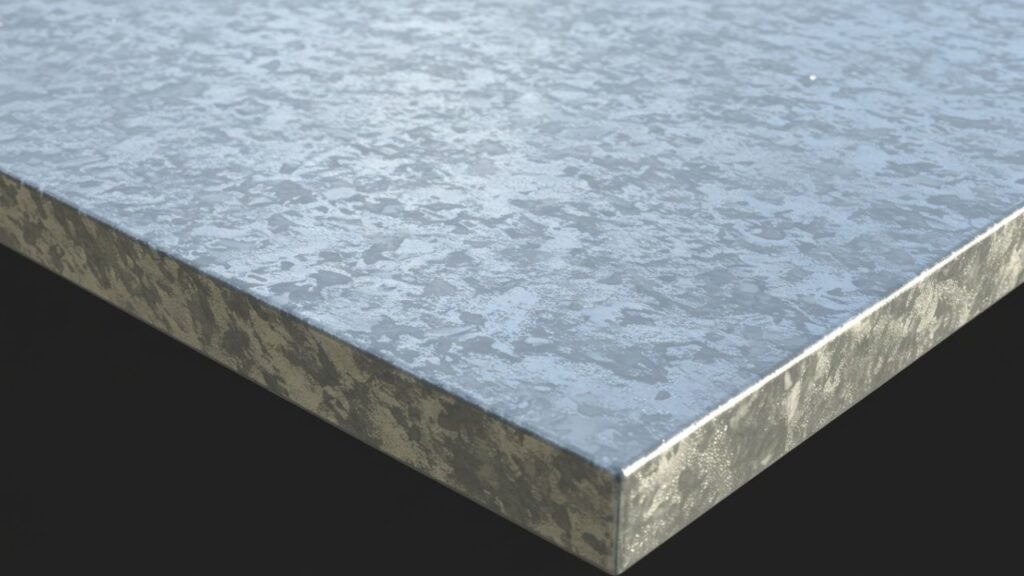

Surface Finish and Aesthetics

A galvanized surface often has a matte, metallic appearance, sometimes with a crystalline or spangled finish depending on the coating method. The coating provides a relatively uniform, protective surface that can also serve as a good base for paint, powder coating, or other protective overlays.

Advantages of Using Galvanized Aluminum

Extended Lifecycle

By protecting aluminum from oxidation and local corrosion, galvanized aluminum typically enjoys a longer service life, reducing replacement and maintenance cycles.

Cost‑Effectiveness Over Time

Although coating aluminum adds cost upfront, savings accrue through lower maintenance, less frequent repairs, and minimized downtime.

Lightweight Solution

Because aluminum is already light, combining it with a thin galvanic coating allows you to keep weight low—a critical factor in aerospace, automotive, and transport sectors.

Versatile Fabrication

Galvanized aluminum can still be machined, formed, welded, or joined using standard techniques. The coating tends not to impede usual manufacturing operations, though special care during finishing or joining may be needed.

Coating Compatibility

Many of the same paints, adhesives, or coatings used on galvanized steel can be adapted to galvanized aluminum, making integration into existing systems easier.

Disadvantages and Challenges

Coating Maintenance

Although the coating is protective, damage (scratches, abrasions) can expose the aluminum underneath. In those cases, repair or recoating is necessary to avoid localized corrosion.

Initial Cost

The additional coating steps (plating, passivation, etc.) raise initial fabrication cost relative to bare aluminum, especially for thick or specialty coatings.

Galvanic and Dissimilar Metal Risks

If galvanized aluminum is paired with other metals, galvanic corrosion may still occur depending on the metals’ potentials. Proper insulation or design must mitigate this.

Thickness Control

Too thin a coating will underperform; too thick may lead to cracking, adhesion issues, or excessive cost. Controlling coating uniformity is key.

Environmental Limits

In extremely aggressive environments (strong acids, bases, or marine immersion), the galvanic layer may wear out faster than expected, requiring more frequent inspections.

Common Applications of Galvanized Aluminum

Architectural & Building Exteriors

Galvanized aluminum is used for façade panels, trim, roofing components, gutters, and window frames—where corrosion resistance and a clean metallic look are desirable.

Transportation & Vehicles

Aircraft parts, automotive body panels or structural components benefit when weight savings combine with surface protection.

Electrical and Telecommunication

Enclosures, housings, and support structures may leverage galvanized aluminum as both a conductive and protective material.

Marine & Coastal Structures

In piers, docks, boat components, and outdoor steel‑aluminum assemblies, galvanized aluminum offers enhanced durability against salt air.

Industrial and Equipment

Machinery, frames, guards, and other industrial components exposed to moisture or chemicals often use galvanized aluminum in lieu of bare or painted aluminum.

Design and Implementation Tips

Proper Substrate Selection

Choose an aluminum alloy that matches your strength, ductility, and corrosion conditions. Some alloys (e.g., 5xxx, 6xxx series) respond better to coatings and field conditions.

Surface Preparation

Before galvanizing, remove oxides, oils, or contaminants from the aluminum substrate. Use chemical cleaning, etching, or microabrasion to promote adhesion.

Coating Process Control

Specify process parameters—plating current, bath composition, temperature, time—to achieve the target coating thickness and uniformity. Use quality controls like thickness gauges or microscopy.

Post‑Treatment and Sealing

After coating, consider sealing, chromate treatments, or topcoats to reduce porosity, improve appearance, and increase durability.

Repair Protocols

Plan for field repairs. Zinc-rich paints, cold galvanizing sprays, or touch-up coatings can help when coatings are damaged in service.

Isolation from Incompatible Metals

If used in assemblies with dissimilar metals (e.g. steel, copper), add insulating barriers (buffers, gaskets) or design joints to mitigate galvanic corrosion.

Inspection & Maintenance

Regular inspection for coating damage is crucial. Touch up scratches promptly to prevent corrosion creep. Clean surfaces to avoid buildup of contaminants that may degrade the coating.

Future Trends & Innovations

Research continues on advanced coating systems. For example, conversion coatings (zirc‑based, chromate‑free) and nanostructured protective layers are being developed to further enhance longevity while reducing environmental impacts. These newer coatings aim for less toxicity (no heavy metals), better adhesion, and self-healing features.

Graphene‑infused overlays are also under study to block corrosive agents more effectively, potentially offering entirely new protective paradigms over traditional zinc coatings.

Conclusion

Galvanized aluminum combines the best of two worlds: aluminum’s lightness and zinc’s corrosion protection. When properly designed, coated, and maintained, it can deliver durable, cost-effective, and versatile performance across architecture, transport, industrial, and marine environments. To succeed, pay attention to substrate choice, coating quality, integration with other materials, and ongoing maintenance. As new coating technologies emerge, the role is poised to expand further into next‑generation applications.